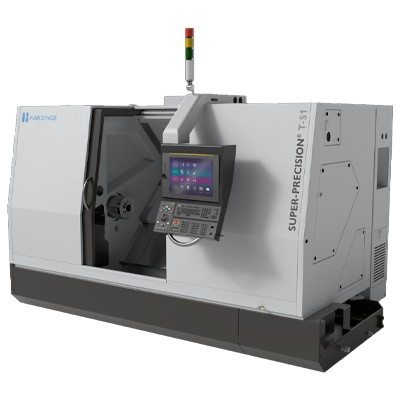

The multi-tasking lathe is available in multiple configurations for both 42mm and 51mm bar capacity.

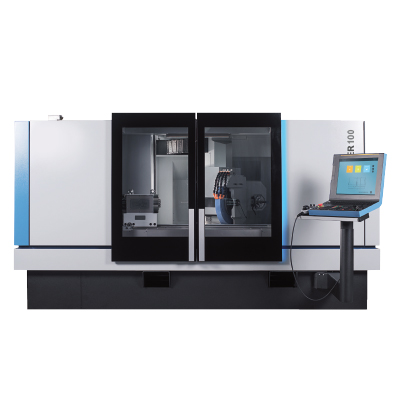

BERWYN, PENNSYLVANIA, USA—July 15, 2020 – Hardinge Inc., the leading international provider of advanced metal-cutting manufacturing tool solutions and accessories, today announced the introduction of the TALENT®TT Multi-Tasking Lathe. The Hardinge Talent TT Series of Multi-Tasking turning centers is available in a variety of configurations and is intended to minimize or eliminate post-secondary operations which often time requires additional machinery and operators. These advanced level turning centers feature twin spindles and twin 16 station turrets for increased productivity, improved part throughput, improved part accuracy, reduced parts handling and reduced part cycle times to increase your profit levels. The machines feature an orthogonal Y axis on the top turret and all stations on both turrets can be live capable for prismatic milling capability.

“This machine truly has all the features you would want from a twin-turret designed turning center. From its rigid design with a small footprint and features like a twin 16 station turret for maximum tool capacity and orthogonal Y axis design on the top turret, it is a great addition to our turning line in the Talent Series.,” said, Thomas Sheehy, Global Turning Products Specialist, “This machine was designed with several different primary and secondary applications in mind to ensure it can be used universally.”

Some of the Key Features of the Talent TT include:

- Talent TT Series

- Two models 42mm and 51mm Bar Capacity

- Standard Bed Configurations

- Twin Spindles

- Twin Turrets

- Compact Footprint

- Primary Spindle Configurations

- A2-5” 42mm Primary Spindle

- 15Hp (11Kw) maximum power

- 68FtLb (91Nm) maximum torque

- 6000rpm maximum speed

- A2-6” 51mm Primary Spindle

- 15Hp (11Kw) maximum power

- 78FtLb (105Nm) maximum torque

- 5000rpm maximum speed

- Control Configurations

- Fanuc 0iTF with Mgi Conversational Programming

- Siemens 828D with ShopTurn Conversational Programming

- Twin Turret Configuration

- 16 Station BMT45 (DIN1809)

- Y Axis feature standard on upper turret

- Lower turret can be used as a tailstock support

- Milling (Live Tooling) “M” Feature

- 5Hp (3.7Kw) maximum power

- 4Ft.Lb. (23.6Nm) maximum torque

- 5000rpm maximum speed

- All turret stations are live capable

- C Axis is included with M feature on all spindles

- Y Axis “Y” Feature

- Orthogonal type construction

- +/- 1.18” (30mm) maximum travel

- Helical interpolation is standard

- Off center turning is standard

- Secondary Spindle “S” Feature

- A2-5” Secondary Spindle

- Can be utilized as a tailstock

- Servo-driven Axis with maximum 1525Lbs (6785N) of thrust

- 15Hp (11Kw) maximum power

- 68FtLb (91Nm) maximum torque

- 6000rpm maximum speed

To learn more about the new TALENT® TT, click here.

About Hardinge Inc.

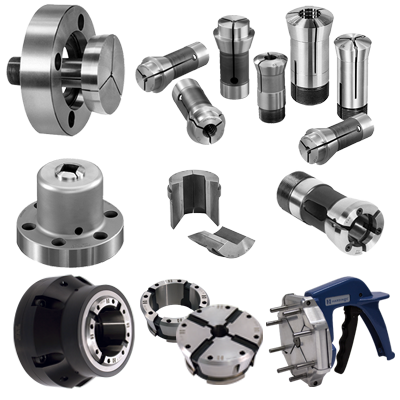

Hardinge, Inc. is the trusted global provider of high precision, computer-controlled machine tool solutions for critical, hard-to-machine metal parts and advanced workholding accessories. With over 125 years of experience, Hardinge offers the largest variety of metal-cutting turning machines, grinding machines, machining centers, collets, chucks, index fixtures, repair parts, standard and specialty workholding devices, and other machine tool accessories. Hardinge’s solutions can be found in a broad base of industries including aerospace, agricultural, automotive, construction, consumer products, defense, energy, medical, technology, and transportation. Headquartered in Berwyn, PA, the company designs, manufactures, and distributes machine tools in over 65 countries across North America, Europe, and Asia. For more information about Hardinge, please visit us at hardinge.com.